First calculate for required voltage by combining total LED forward voltage and driver voltage drop of 2V. LED forward voltage of each strip = 3.5V x 12pcs = 42V Driver circuit required voltage = 42V + 2V = 44V LED total current requirement = 0.7A X 4 strips in parallel = 2.8A Driver circuit required wattage = 44V X 2.8A = 123.2W LED power supply’s rated voltage/power should be greater than what is required but should be as close to the actual requirement as possible. Use 48V/150W as the basic criteria to pick LED power supply then make sure actual voltage/power usage meets constant current region and PF>0.9 specifications (123.2W /150W = 82.13% >75%) CLG-150A-48 with output voltage set at 44V can be used in this design.

Same LED configuration as in question B1 with the exception of additional driver ICs. What is a suitable power supply unit to use?

Posted by

–

Recent Posts

- The AC-DC reliable green industrial adaptor is a crucial component in many industrial applications.

- Reliable Ultra Wide Output Range Battery Charger & Power Supply

- DC Centralized Bus Lighting Solutions

- Advantages and Challenges of High-Voltage DC Output Power Supply Solutions

- LED Fishing Lighting: A Revolution in Angling

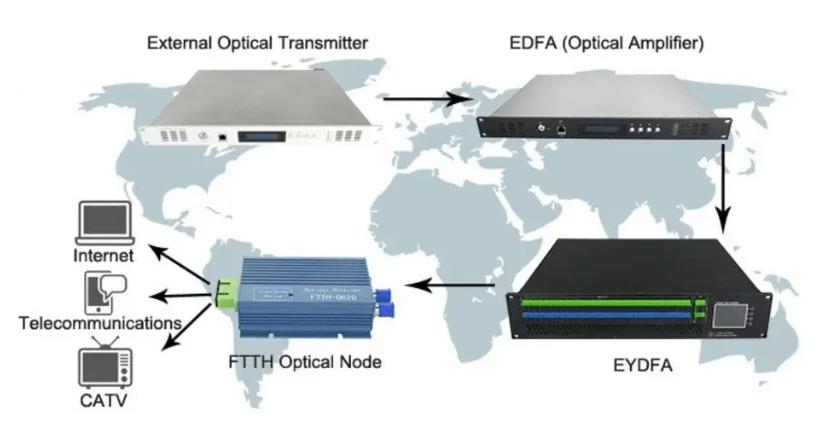

- 5G Telecommunications Equipment Power Supply Solution

Tag Cloud